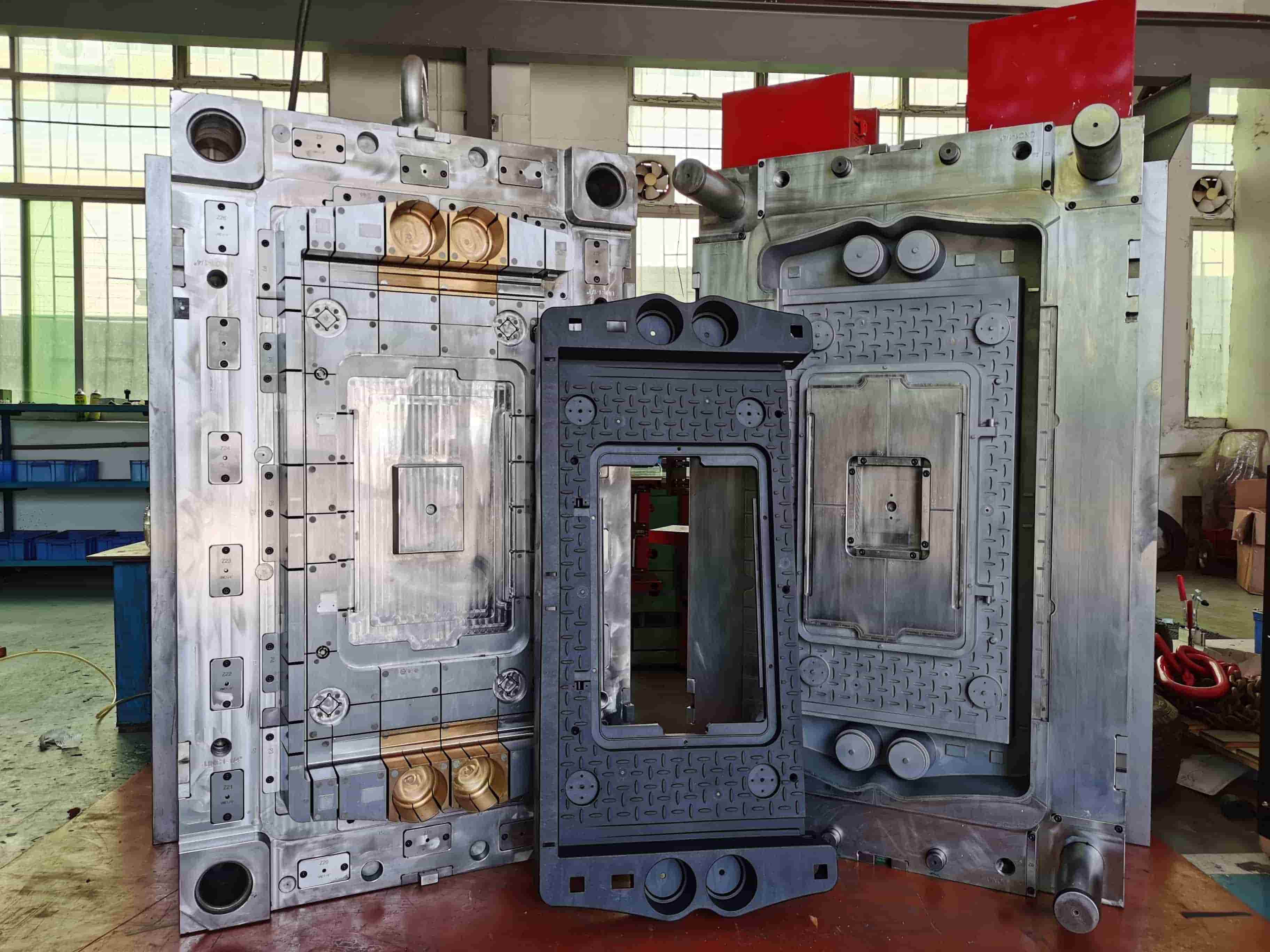

5 Injection mold type based on US SP1-SPE standard

If you need to develop a product or project, hardware equipment is an inevitable carrier, and plastic casings are currently very popular. The production of plastic shells must be inseparable from injection molds. As a Chinese injection mold manufacturer and supplier, we have more than 10 years of export experience and are familiar with the mold requirements of customers in different countries. Today we will talk about what the mold categories of the US SP1-SPE standard are, and I hope it will be useful to you.

1. Class 101 molds (SP1-SPE standard 1,000,000 beer or more, long-term precision production molds)

1). Detailed mold structure drawings are required;

2). The minimum hardness of the mold blank material is 28HB (DME #2 steel/king material electroplating nickel/P20 electroplating Nickel);

3). The steel of the inner module with glue must be hardened to 48~52HRC, and other parts such as row positions, press locks, beading, etc. should also be hardware;

4). The ejector plate must have guide posts;

5). Rows

6). If necessary, the upper mold, lower mold and row position must have temperature control;

7). For all water channels, it is recommended to use electroless nickel dipping or 420 stainless steel as the template, which can prevent rust and clean up garbage;

8). A straight lock or oblique lock is required.

2. Type 102 molds (no more than 1,000,000 beer, mass production of molds)

1). Detailed mold structure diagram is required;

2). The minimum hardness of the mold base material is 165BHN (DME #2 steel/AISI1050);

3). Internal modules with glue positions The steel must be hardened to a minimum of 48~52HRC, and other useful parts should be treated in the same way;

4). It is recommended to use straight locks or oblique locks;

5). The following items may or may not be required, depending on the final production quantity. It is recommended to quote When using the following items, check whether it is necessary: A. Ejector plate guide post, B. Row position hard sheet, C. Electroplating water delivery hole, D. Electroplating mold cavity.

3. Type 103 molds (less than 500,000 beers, medium-volume production molds)

1). A detailed mold structure diagram is required;

2). The minimum hardness of the mold base material is 165BHN (DME #1 steel/1040 steel/S50C);

3). The steel material of the inner mold is P20 (28~32HRC) or high hardness (36~38HRC) ;

4). The rest of the requirements depend on the needs.

4. Type 104 molds (less than 100,000 beer, small production molds)

1). Detailed mold structure diagram is required;

2). Mild steel or aluminum (1040 steel) can be used for mold base material P20 (28~32HRC);

3). Internal molds can be used Aluminum, mild steel or other approved metals;

4). Other requirements depend on the needs.

5. Type 105 molds (less than 500 beers, the first mold or test mold)

Aluminum casting or epoxy resin or any material can be used as long as it has enough strength to produce the minimum number of tests.

Post time: Jul-10-2023