Aluminum die casting is a process in which molten aluminum alloy is forced into a steel die or mold under pressure. It is usually employed for mass production and can produce parts with highly intricate details as well as components with very tight tolerances at a relatively low cost. The parts produced from aluminum die casting have excellent mechanical properties and are resistant to corrosion, heat, and wear.

• Aluminum die casting offers a number of benefits, some of which include:

• Lightweight and strong components that are more cost-effective than other types of metals

• Improved efficiency due to shorter lead times and reduced waste

• Increased design freedom due to its malleability, allowing complex shapes to be created quickly and easily

• Greater resistance to corrosion, heat, and wear compared to other metals

• Ability for mass production, with most aluminum alloys able to withstand high pressure and temperatures

Aluminum die casting is an incredibly versatile manufacturing method used to produce a wide range of parts for various industries. From automotive components to medical implants and more, aluminum die casting can be used to create almost anything, such as:

• Automotive industry: A variety of parts including interior trim, transmission casings, engine blocks and mountings, radiators, and charging systems.

• Aerospace industry: Complex components such as pumps, sensors, actuators, radio towers and antennae.

• Medical industry: Highly specialized components such as implantable heart valves, surgical instruments, orthotics and prosthetics.

• Household appliances: Hinges and latches for refrigerators and washing machines as well as other small components that require intricate detail work.

• etc,.

Choosing the right aluminum alloy for your die casting project is essential to ensuring that your finished product meets all of your specifications. Here are some tips on selecting the right alloy:

• Consider the strength and durability requirements of your part. Different alloys offer varying levels of strength and wear resistance, so it's important to choose an alloy that will meet the needs of your application.

• Evaluate the required corrosion resistance level. Aluminum alloys can be treated and anodized to provide additional protection against corrosion, so make sure to consider which environment your parts will need to endure.

• Consider production costs and delivery times. Depending on the complexity of the part, different alloys may require different production methods or tooling investments, so it's important to weigh these factors when selecting an alloy for your project.

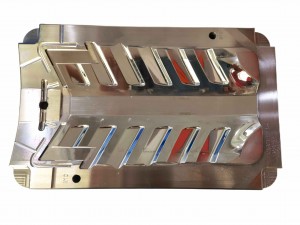

Tooling and machining requirements for aluminum die casting vary depending on the alloy used, the complexity of the part, and other factors. Generally, it is important to consider the following when selecting a tool type:

• The choice of tool material should be based on the alloy being used and the temperatures needed in order to produce quality results. We normally use H13, SKD61, 8407, 8418, 8433 and W360 for die cast tooling.

• Care must be taken to ensure that there is sufficient draft angle so that components can easily move away from the die when ejected. A complete DFM analysis should be done before mold design.

• Second machining may be required after casting in order to achieve certain shapes or details, it includes CNC machining, drilling, tapping and so on.

• Surface Finishing options such as sand-blasting or vibratory polishing, anodizing, plating or painting may also be necessary depending on your needs.

CNC Machining for Die Casted Parts

Troubleshooting common issues in aluminum die castings can be a time-consuming and costly process, but it is essential to ensuring the quality of your components. Here are some tips on troubleshooting common issues with aluminum die castings:

• Porosity: Examine your part for any pinholes or other areas that could lead to porosity. If you find any, make sure to review the mold temperature, injection pressure and other factors that may have affected the filling of the piece.

• Distortion: If you find distortion in parts after they have been removed from the die, check to see if the mold design or cooling times might be causing this issue. You may need to adjust these settings for future production runs in order to reduce any distortion.

• Surface defects: If you encounter any surface defects such as splay marks or fins, check whether there is a mismatch between injection speed and melt flow rate, as this can often cause these issues. It may also be necessary to adjust casting parameters such as temperature and cooling rates in order to minimize surface imperfections.

When a new project started, rapid prototyping parts are needed for kinds of testings. There are many ways to make prototypes including CNC machining, Vacuum casting, 3D printing and Rapid prototype tooling.

• CNC machining can make metal and plastic parts with any quantity.

• Vacuum Casting is for 5-100 unit plastic parts by using silicon molds

• 3D Printing is to print ABS, PA or Steel parts. For plastic, 3D printed parts can’t stand high temperature.

• Rapid prototype tooling is soft mold made by soft steel like S50C or Aluminum. This solution can produce much more parts than Vacuum casting. Lead time is shorter than production tooling and price is lower too.

Materials we have used: Plastics like PC, PMMA, POM, PP etc,. Metal like steel, aluminum, brass, copper and so on.

How to make a silicon parts

To create a silicone part, you will need to use the process of injection molding. This involves melting plastic in an injection machine and injecting it into a closed cavity, where it cools and hardens to take the desired shape.

Other processes you could use include press molding, vacuum casting, or 3D printing. Each method offers unique advantages and disadvantages depending on what type of part you are trying to create.

With all methods, getting the right temperature and pressure is key for achieving accurate dimensions and desirable materials properties.

Appliances of silicon parts

There are many industrials can use silicon soft parts such as Automotive, Medical, Electronic, houseware, kitchenware, and many others. For parts, usually you can find these like Gaskets, Seals, O-rings, Air filters, Hoses, Lighting components, Cellphone cases, Keyboard covers, Wires and cables insulation and many Medical devices.

Metal stamping parts are metal components created through the process of metal stamping, a manufacturing technique that involves punching, cutting, or forming metal sheets into desired shapes.

Metal stamping is used to create parts for a wide variety of industries including automotive and aerospace industries.

It can also be used to create custom and intricate shapes. Benefits of using metal stamping include cost-effectiveness, design complexity and flexibility.

SPM has helped customers in many metal stamping goods for their turnkey project, our effective engineering service can save a lot of their cost and time.

Jigs and fixtures are tools used to aid in the manufacturing process of various parts and components.

A jig is a specialized tool that helps guide, hold, or position a workpiece in place during different machining operations, such as drilling, milling, and shaping.

Fixtures are devices that are attached to the machine or workbench and help locate and secure the parts while they are being worked on.

They can be custom designed to accommodate a variety of tasks to ensure accuracy and efficiency.Both jigs and fixtures can be made of metal such as steel or aluminum and are essential for producing accurate components with minimal effort.

SPM makes jigs and fixtures for our own injection molding production and also provide service of making them to customers.

If you have demand of this, please contact anytime.