-

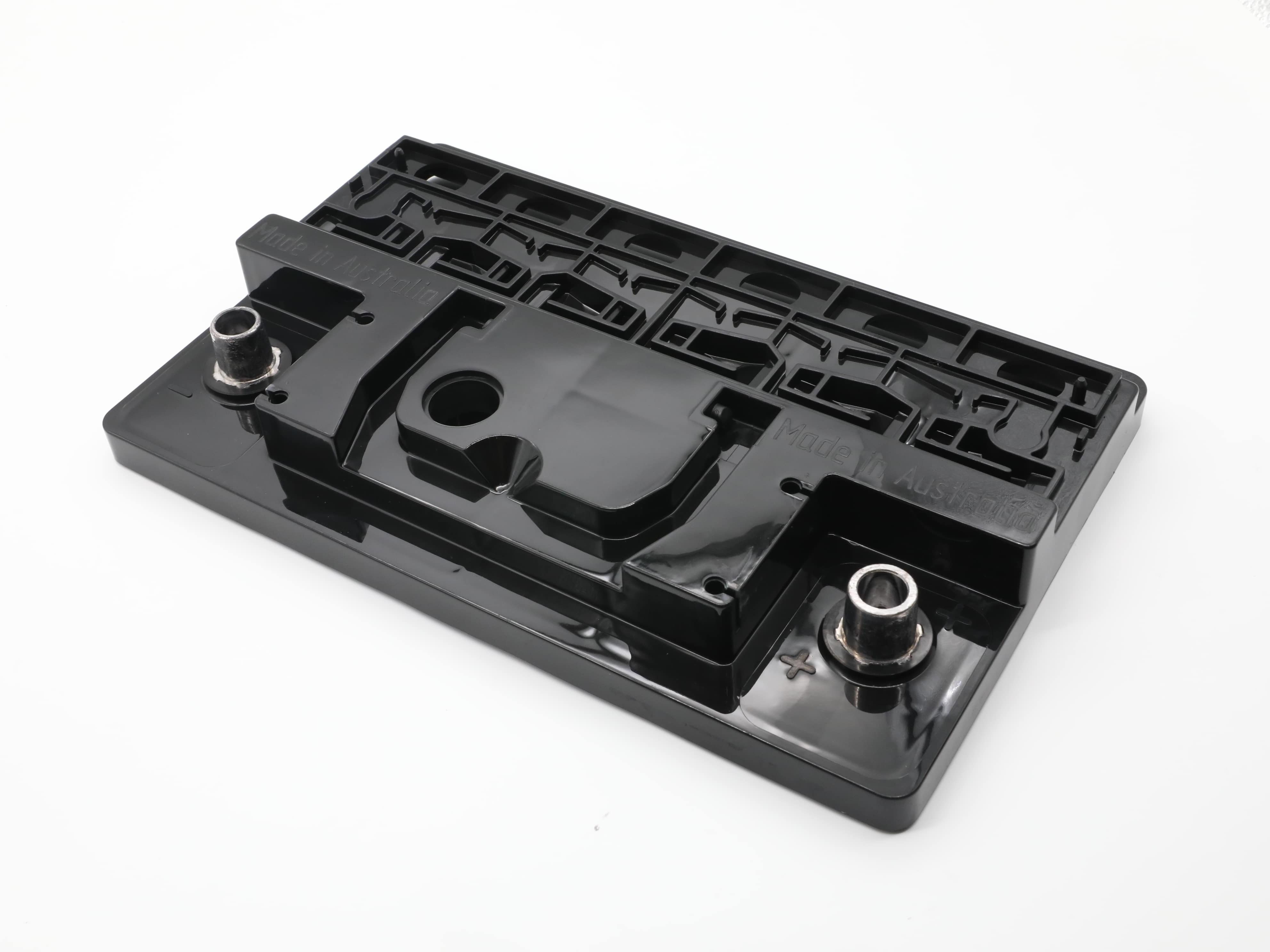

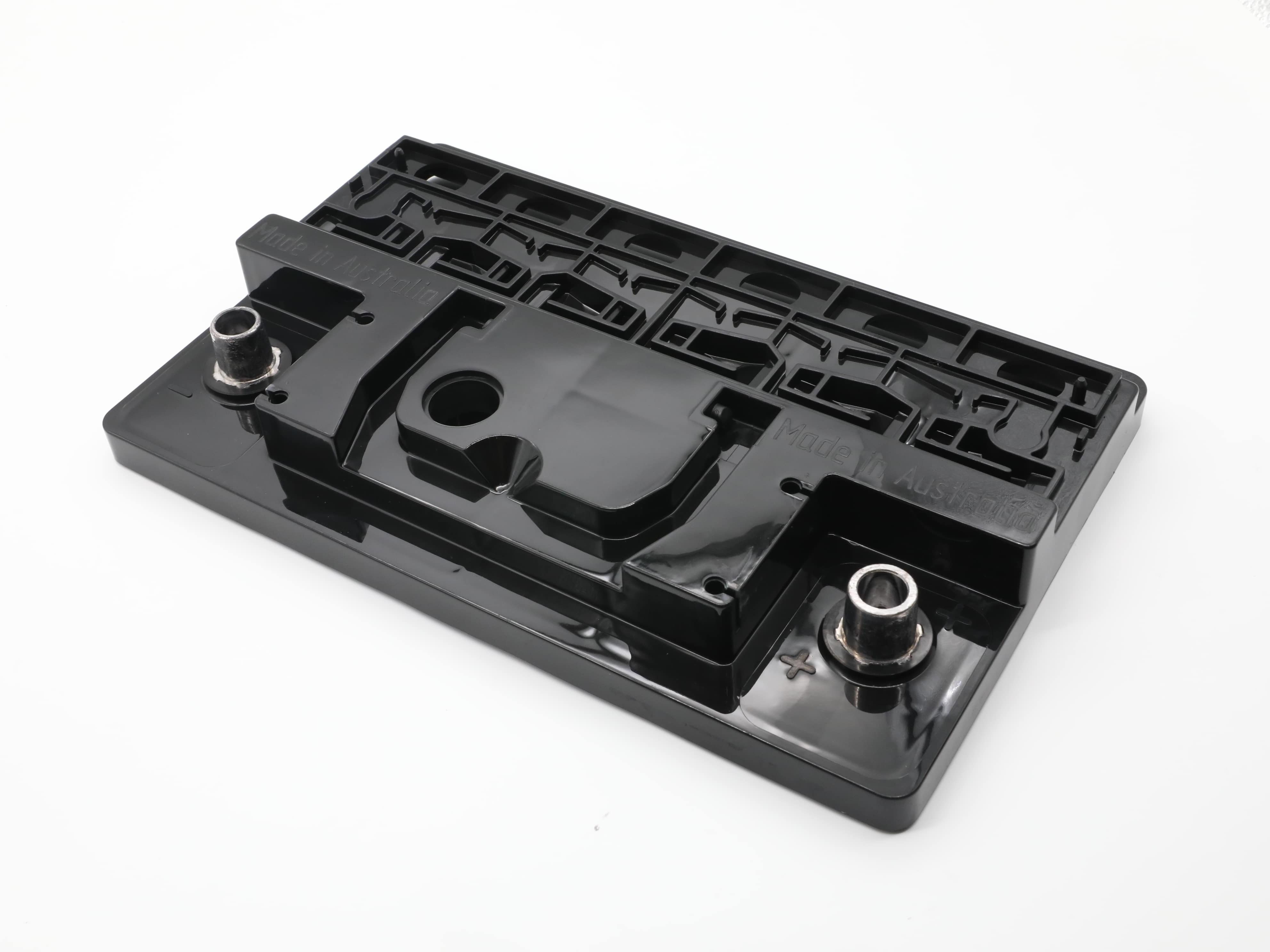

Suntime Precision Mould has made many similar battery lids and boxes with different size. The surface is A-3 polish. T here are many ribs inside in the battery lid and need to do very well in mould... Plastic injection mould insert mold for Automo...

more -

This is 16 cavity mould. Mould delivery after T1, finished in very short time. Because the inside thread needs to be released by force, we need to make sure there is no scratch mark when demolding ... Injection multi cavity mould for caps of packa...

more -

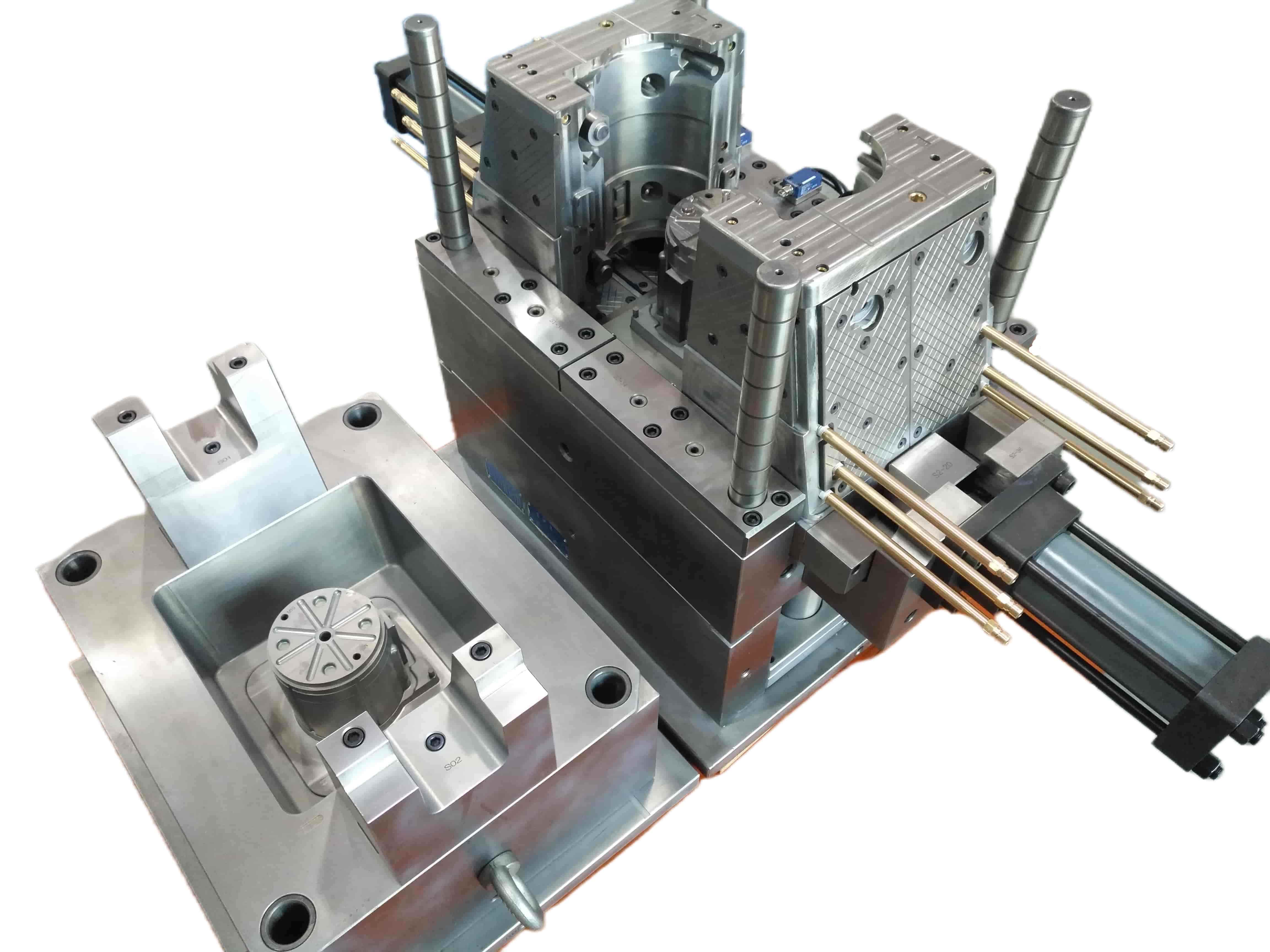

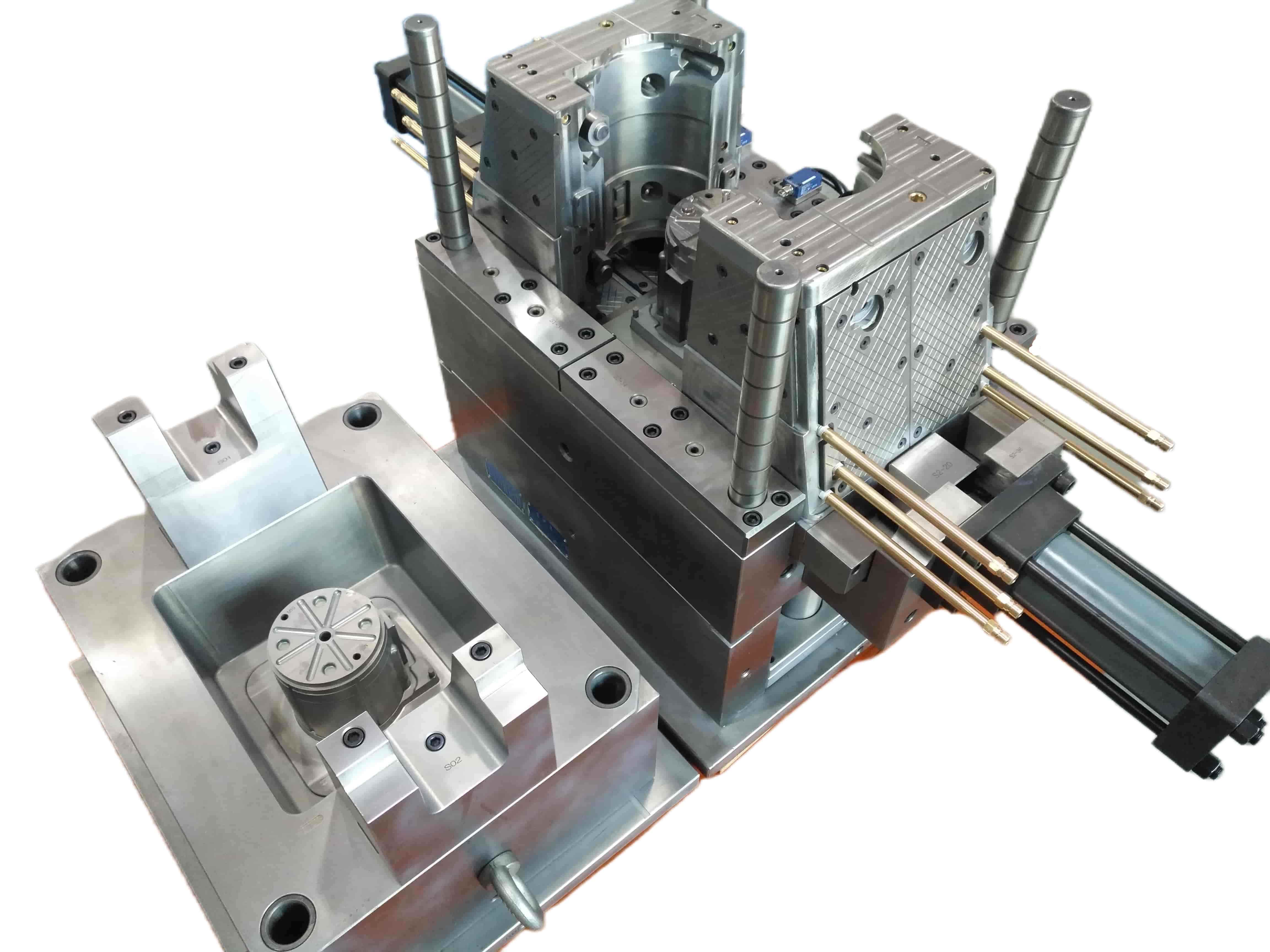

Plastic injection molded part for mining industry. The product weight is around 4.8Kg. Nylon plastic with 45% Glass fiber. H13 hardened steel for the mold manufacturing. This plastic is very specia... High glass fiber Nylon material mold tooling fo...

more -

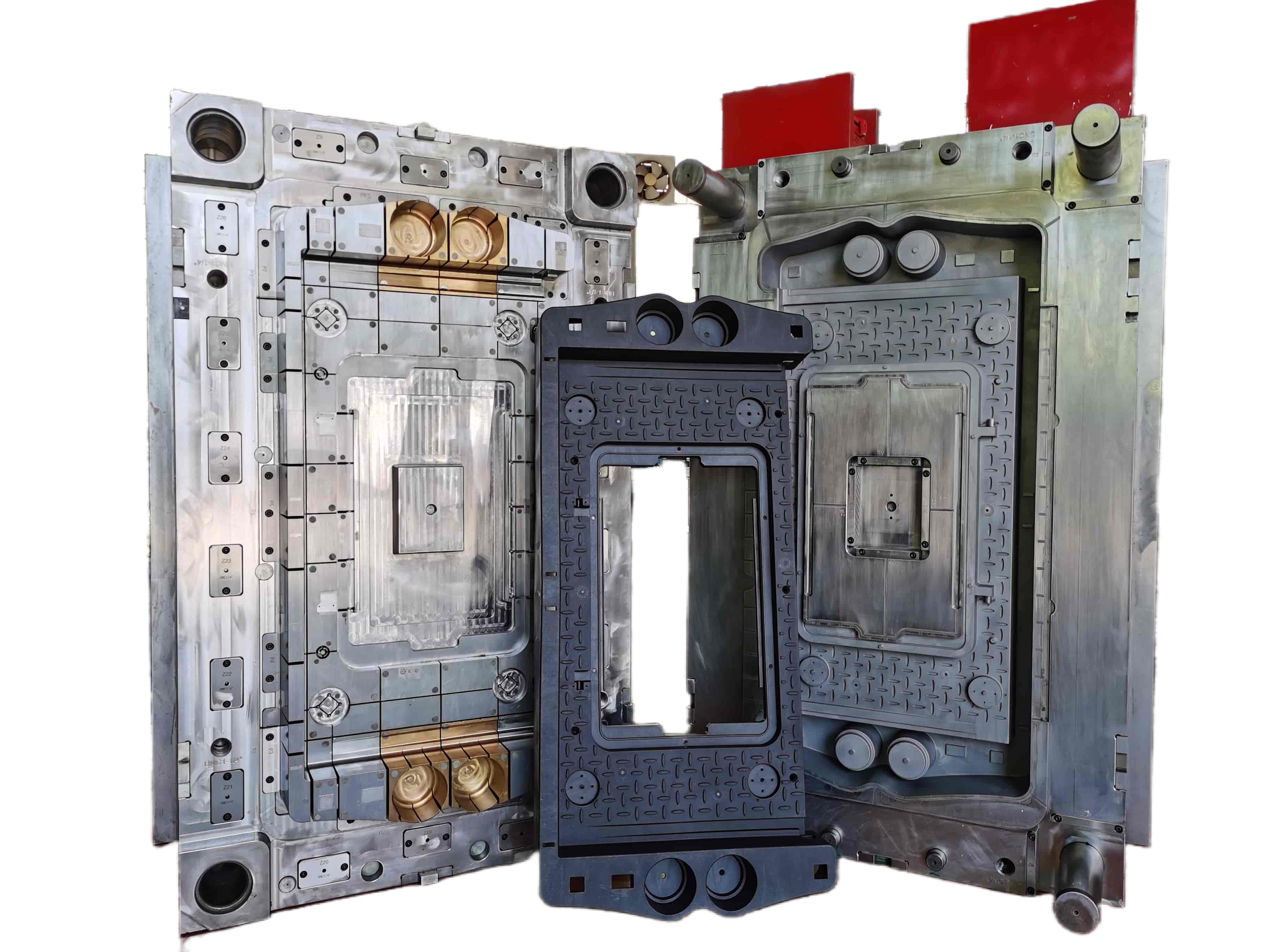

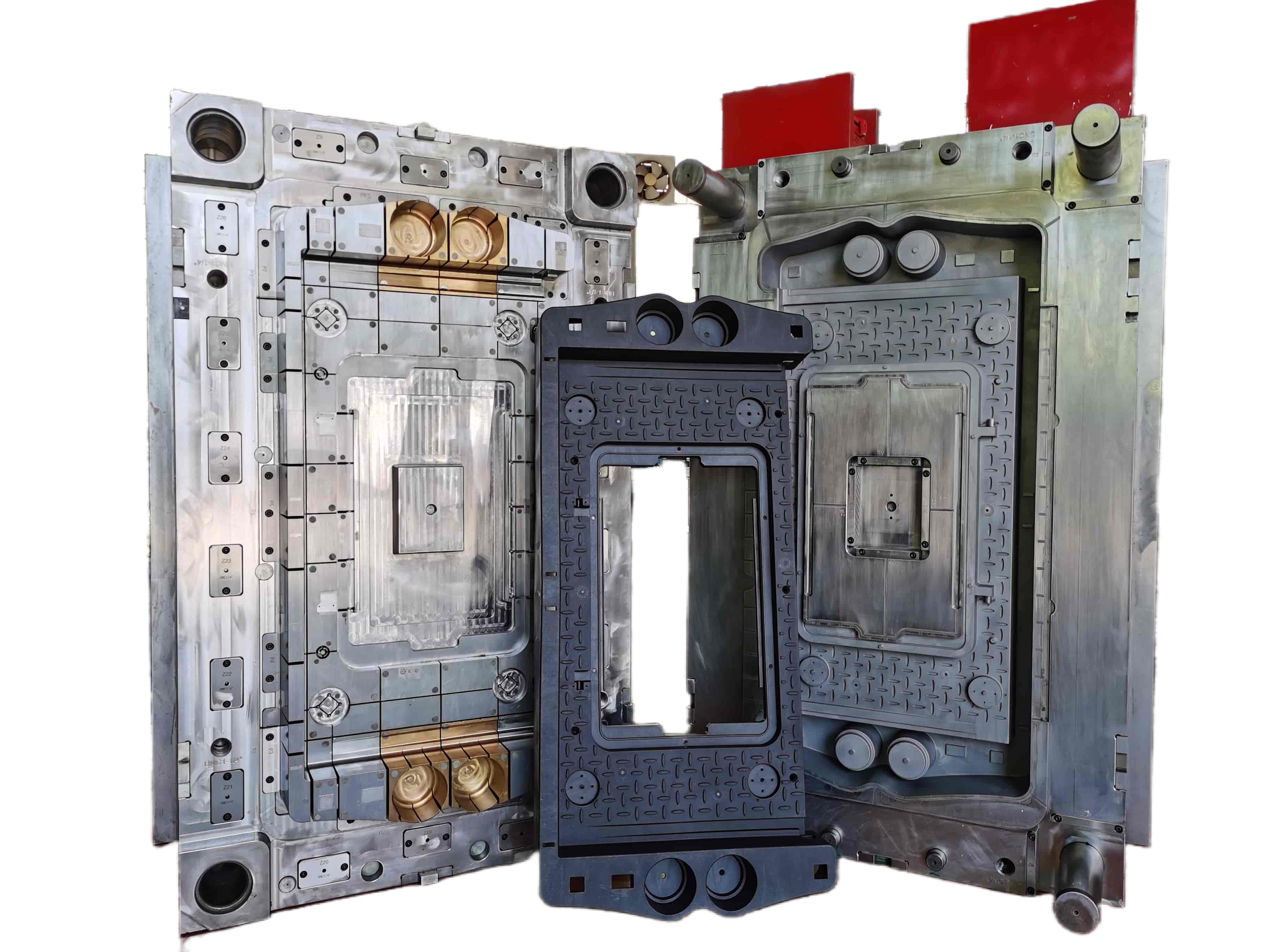

This product is one of the components for gold cart. Part is big and have deep ribs, need to do well to control the warpage. We used Becu inserts for cooling in deep rib area. Besides on controllin... Big size plastic injection mould for automotive...

more -

• The high temperature auto unscrewing project has mold temperature of 160 degree and resin temperature of 380 degree. • This 4 cavity mold has total cycle time of 35 seconds with very smooth ... Auto unscrewing mould making & High tempe...

more -

These products are the very nice. Suntime Precision Mould spent 4.5 weeks for manufacturing. It is for car tail lighting with surface A1 polishing. The main difficulty is tooth profile and how to c... Plastic tooling family mold automotive tail lig...

more -

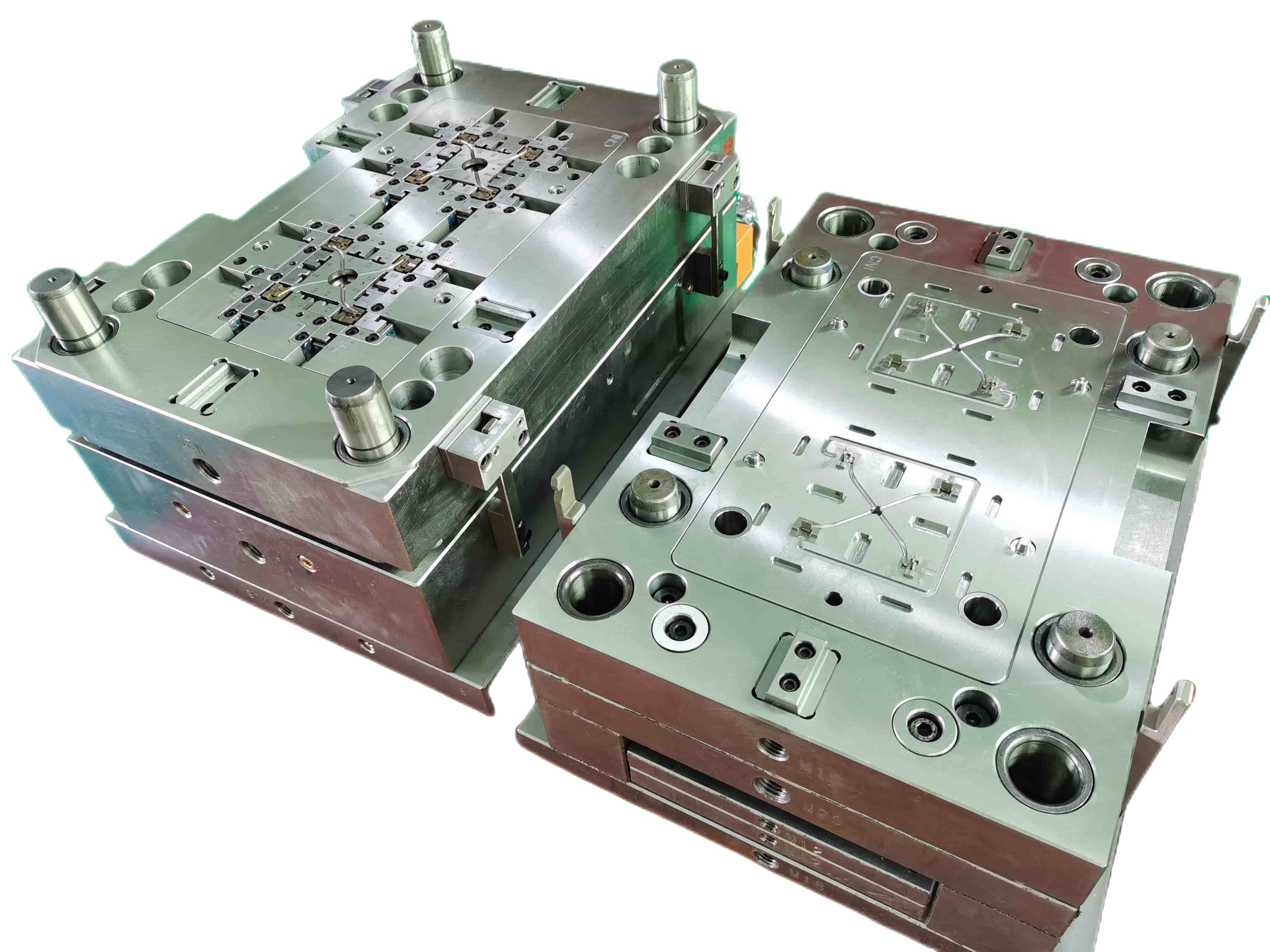

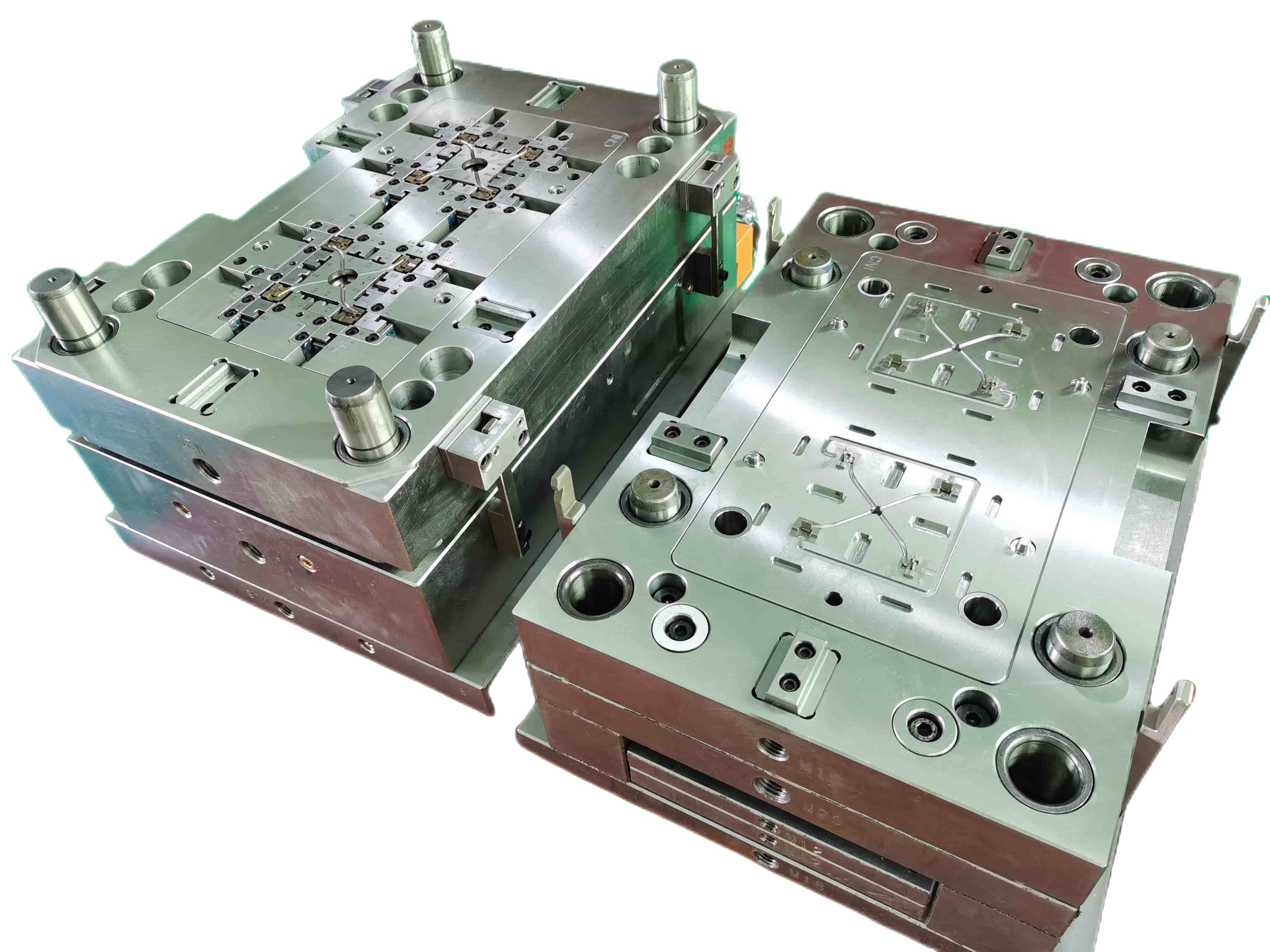

Appliance and Type Electronic precision components made by multi cavity plastic injection mould, Part name Mobile connector Resin Powder metallurgy materials No. of cavity 1*8 Moul... Precision plastic injection mould for consumer ...

more -

This project was placed to Suntime mould from rapid prototyping to tooling and injection moulding. The housing surface is Mold tech texture and there is silk printing in the middle housing. The par... Plastic injection moulding project from Rapid p...

more