These are the 3 points for high temperature mould with PPSU resin

What is the the advantages for PPSU material?

The short-term temperature resistance of PPSU plastic is as high as 220 degrees, and the long-term temperature can reach 180 degrees, and it can withstand the oil temperature environment of 170-180 degrees. PPSU parts have good dimensional stability, and can withstand hot water/refrigerant/fuel oil. With this excellent property, PPSU can be used to produce high-quality technical and high-load products. It now becomes the first material to replace metals, ceramics and hard polymers.

PPSU plastics are increasingly used in preparation and reheating of hot meals, especially for high voltage components that must have high dimensional stability and good mechanical & good electrical insulation properties as well as high thermal aging resistance, excellent fire resistance, and good resistance to chemical corrosion and hydrolysis.

With this, it becomes an important material in wide range of applications in industries such as aerospace, electrical and electronic components, automotive and transportation.

How to do temperature control for PPSU molding?

As with other engineering thermoplastics, the stable production of high-quality molded parts requires precise control of the temperature of the high temperature injection mold. Both water and oil can stably control the mold temperature between 140 and 190 degrees. If the temperature control equipment is good designed, water about 200 degrees can be used as the temperature control media. Electronic temperature control can also be used in certain cases. Before injection molding, The PPSU material should be dried, we suggest to dry the material with temperate of 150-160 degrees for 3-6 hours. The barrel of the injection molding machine should be cleaned enough. And the injection temperature is recommended to be controlled around 360-390 degrees.

How to make the high temperature injection moulds for PPSU material?

The injection mold for PPSU material must be able to withstand relatively high temperatures as a high temperature molding tool. In addition to adopting reasonable mechanical design and selecting appropriate mould materials, heat-resistant and pressure-resistant hoses should also be used to optimize the design of cooling channels, seals, and connectors.

Design Points:

1. Selection and treatment of steel: a). The mold temperature should be based on 140 to 150 degrees, and the life of the mold should be considered in mass production. b). The mold heat treatment is required to be HRC60-65 overall. c). Electroplating treatment can increase the molding service life.

2. Runner shape: round or trapezoid is suitable. A cold slug well is also required.

3. Gate types: Pin point gate, tab gate, disk gate, spoke gate, side gate, direct gate and sub gate.

4. Gas Venting: Venting is very important for PPSU material mould. Venting not enough will cause burnt, color-change and rough surface and so on. The gas vent is normally 0.015~0.2mm height and over 2mm wide.

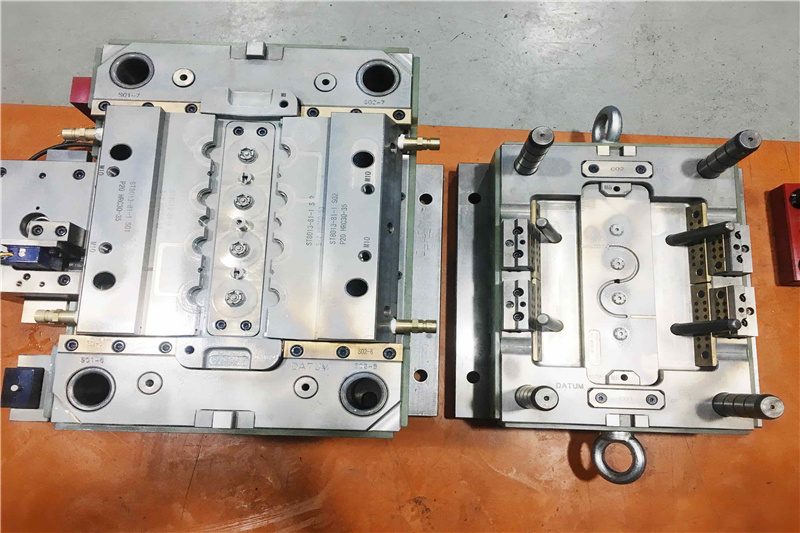

Suntime Precision Mould has rich experience of plastic injection mould making for high temperature mold for material like PPSU and PEEK. Customers are very happy with our high quality and fast lead time. Below photo is one of the high temperature mold we have made for plumping & fitting parts. It is a 4 cavity auto-unscrewing mould. For more information about this kind of moulds, please check our case study in website: https://www.suntimemould.com/auto-unscrewing-plastic-injection-mould-with-ppsu-material-high-temperature-mold-product/

Post time: Dec-18-2021